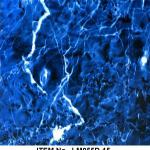

newest black carbon water transfer printing foil for mouse - YZC-414

| Material Type: Film | Material: PVA water transfer printing | Application: Application for Commodity,Electronics,Aoto\Shoes\Leisure Industry,glass;wood;metal;ceram;plastic.... | Type: Water Transfer |

| Place of Origin: Guangdong China (Mainland) | Brand Name: szzhichao | Model Number: YZC-414 | condition of storage: temperature:22℃; humidity:55% |

| gross weight: about 12kg one roll | Standard size: L*W=500*0.5meter |

Water transfer printing film

serviceS

1.provide various kinds of water transfer printing film; designing and developing new patterns as your requirement

2.provide whole set of water transfer printing equipment(dipping tank;washer machine;oven/drying ling;spraying oil machine

3.provides whole factory facilities and technology transfer sevices

4.activator can be provided

- advantage of film

- The blank film import from Japan ,the tension and adhesion of the film is strong and good for operation ;

- We have our own chemist and designer group , so we could custom your film at any time ;

- The thick of film is 30 Micro,the disolve time of film is shorter than commom film , it is good for mass production

application

Auto industry: steering wheel,head of gears,cup holders,frame,lock,

shoes industry:all kinds of vamps

Electronics:Oxygen bar,air purifier,phone,remote control,acoustics,clock and watches...

commodity:all dinds of crafts,beauty-chairs,glasses boxes,glasses boxes,bottles,pot...

leisure industry:fishing gear,fishing rod,travel goods,hunting supplies,ice skate...

What temperature and humidity is best to store film You must store the film properly to ensure long shelf life and proper decorating. The film must be stored in a humidity and temperature controlled environment. |

Water transfer printing process

Water transfer printing (hydrographics, aqua printing, cubic printing, hydro imaging...) process can be applied to the surface of the materials such as hardware, wood, plastic, stone, bakelite, ceramic, etc. The cost of products that have been applied with water transfer imaging is relatively low, while their added value multiplies.

Water transfer printing process consists of these steps :

1. Film selection - Choose an image from our library of more than 1000 standard water transfer printing films, or we can produce an individual printable image made from a sample pattern or photograph.

2. Base painting - If necessary, the objects to be printed will be base painted in an appropriate color (for instance, brown would be used for parts which will be printed in a wood grain image). It should be noted that the same film pattern's end result can be manipulated simply by changing base colors to get the desired effect.

3. Preparing the film - The printing film is laid onto the water surface of the dipping unit. The carrier substance on which the pattern is printed dissolves while the pattern itself remains floating on the water.

4. Film activation - The floating image is treated with a special activating liquid which dissolves the components in the pattern's colors without affecting its structure and appearance.

5. Transfer - The item is immersed in the water through the floating layer of liquefied pattern. The pressure of the water will cause the pattern to smooth itself evenly around the object in all places and adhere to it. The end result is the part completely covered in the pattern of your choice.

6. Washing and drying - The printed parts are washed to remove any residue of the printing film and are allowed to dry.

7. Clear coating - After undergoing an inspection (quality control) the printed objects are clear coated if desired to protect the printed surface. Anything from a completely matte clear coat to full high gloss can be applied.

| Packaging Detail:Inside packing : The first layer packing with tinfoil film;The secnd layer by waterproof film;the third layer by Bubble bag. Carton Box :L*W*H=55*42*22cm /55*22*22cm Shipping term depends on your ordering quantity |

| Delivery Detail:5 Working days after confirm the payment |