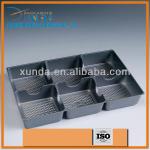

OEM thick ps plastic tray for machine,vacuum thermoforming,Amei Brothers - OEM

OEM thick ps plastic tray for machine,vacuum thermoforming,Amei Brothers, Thick ps tray, 0.14-10mm thick - details see: https://www.packinghere.com/oem-thick-ps-plastic-tray-for-machine-vacuum-thermoforming-amei-brothers-10005507

| Type: Tray | Material: Plastic,ps | Plastic Type: PS | Use: Food |

| Process Type: Blister | Custom Order: Accept | Place of Origin: Guangdong China (Mainland) | Brand Name: OEM Thick ps tray |

| Model Number: OEM | product name: OEM thick ps plastic tray for machine,vacuum thermoforming | color: coloful | thickness: 0.14-10mm |

| size: the max is 3000*2000*800mm | shape: customized | usage: plastic tray | feature: cheap,impact-resistant |

| color process: print,painting,electroplating,etc. | product type: Thick ps tray |

OEM thick ps plastic tray for machine,vacuum thermoforming,Amei Brothers

Thick ps tray

0.14-10mm thick

products details:

| item name | OEM thick ps plastic tray for machine,vacuum thermoforming,Amei Brothers |

| color | coloful |

| material | ps |

| thickness | the max is10mm |

| size | the max is 3000*2000*800mm- |

| process type | vacuum forming |

I. What's vacuum forming ?

Vacuum forming is a process in which a thermoplastic sheet is heated to the appropriate temperature, stretched around or into a mold or pattern, and conformed to the mold by applying vacuum pressure between the mold surface and the plastic sheet. Because heating of the material to be formed is required, vacuum forming is considered a thermoforming process.

II. Vacuum Forming Machined process :

| 1. Extruding plastic sheet: | ABS, HIPS, PP, PE, PC, PMMA resin granules are extruded or co-extruded into thermoplastic sheet or plate that textured, smooth, gloss or matt, fire retardant and UV resisted |

| 2. Vacuum forming: | After being heated, the plastic sheet is stretched onto or into a mould, and held against the mold by applying vacuum between the mould surface and the sheet to form designed shapes. |

| 3. Cooling to keep shape: | Once formed the plastic need to cool before being released from the mould. To speed up the cooling cycle, fans are fitted and activated once the plastic part is formed. |

| 4. Machine large products: | Our machine could be restructured to make larger plastic vacuum forming plastic products, with maximum dimensions of 3000*2000*800*10mm (L*W*H*T) |

| 5. Trimming edges: | Extra material is firstly trimmed before more accurate processing. Sawing is often used in the stages. Polishing is made additionally to smooth the edges. |

| 6. Drilling holes: | Drilling often follow the trimming. Other post forming processes include decoration, printing, strengthening, reinforcing and assembly. |

| 7. CNC Processing: | For more accurate and faster speed vacuum forming plastic products processing, CNC is often used. The machine is computer programmed to select correct cutting tools and angle to suit each area. |

| 8. Examination and checking: | Before packaging, all our vacuum forming plastic products will be carefully checked in terms of dimensions, surface finish, strength, color requirements and so on. |

| 9. Cleaning and Packaging | All vacuum forming plastic products are cleaned before packaging. Products are wrapped with plastic film to prevent scratches and cartoon boxes are used or other methods are applied as required. |

Our edge:

- We are able to do silkscreen, plating, spraying.

- We can add your own logo. we are largest manufacturer of vacuum forming products as customer design in Shenzhen,

- We have our own experienced mould technicians and CNC mould machines.

- We have adopted vacuum thermoforming method in order to minimize the product development cost for customers; we provide one stop service including mould design.

- Welcome to order!

| Packaging Detail:polybag+carton,OEM Thick ps tray |

| Delivery Detail:7-20 days,OEM Thick ps tray |